Sometimes things just go sideways

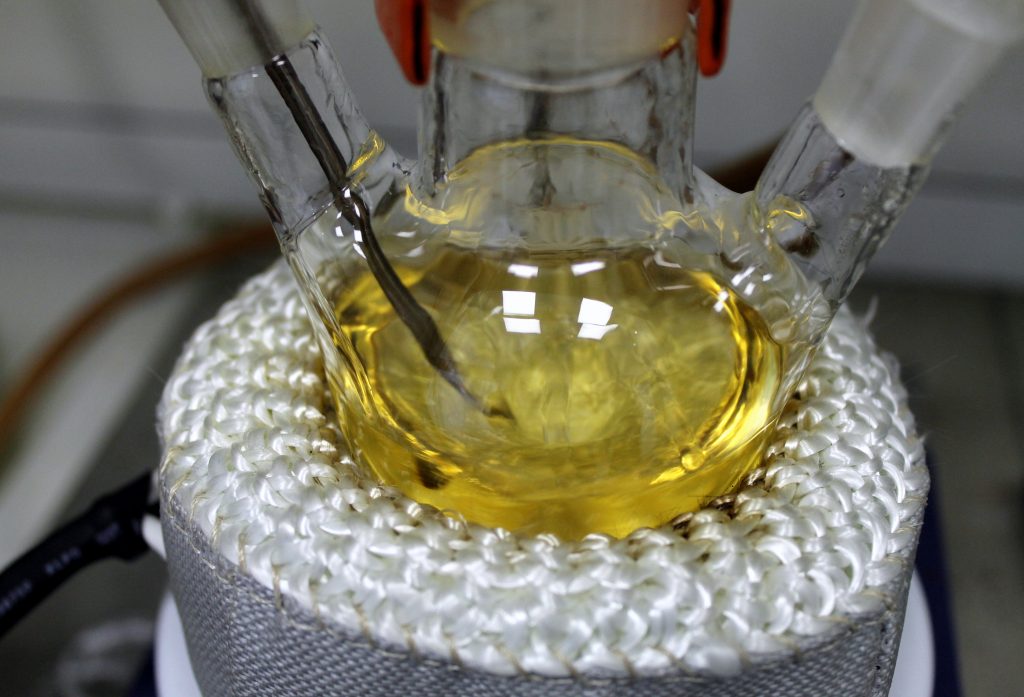

I was working with a client conducting cutting-edge research recently when they experienced something completely unexpected. A slight over-pressure in a glass reaction vessel caused one of the ground glass joints to unseat itself and ejected a goodly portion of the reaction mixture into the hood. This particular reaction was a small, albeit a two-fold scale-up (200 mL in total volume) from a previous reaction that was not remarkably energetic. No overexposure or fire resulted – it was just a mess. From a research safety perspective, the investigators did everything right: the reaction was contained in a properly operating hood with the sash down; appropriate PPE was in use, good control on the heating mantle; etc.

The organization has a culture of investigating out-of-normal events, and a meeting was held to try to figure out the “whys” behind this one. It was clear from the outset that one meeting wasn’t going to find the root or even solid contributing causes to the event, but one thing did emerge from the discussion: when you’re on the bleeding edge of research, sometimes things just go sideways.

Focusing On What Went Right

We spent a considerable amount of time reconstructing the events prior to the incident and post-incident actions. The research team had a strong safety culture which included controls for the reaction in the event of a release and a solid, management-approved standard operating procedure that allowed for scale-up. Performing the reaction in a hood was key to preventing a larger mess in the laboratory and subsequent unnecessary chemical exposure. All of the temperature control equipment was properly operating, and the reaction was attended. Nothing out of normal appeared to be occurring, at least until the over-pressure and release of material into the hood. At the end of the discussion, we agreed to repeat the experiment at 0.5x and 1.0x scale and make careful observations as the temperature increased. The results of these experiments did not produce any remarkable observations. The group is now doing some calorimetry to understand their system better.

Risk Assessment and Risk Acceptance in Research

One of the key elements of the group’s standard operating procedure was a risk assessment of the proposed work. The assessment included the proposed chemistry and the methods used to keep the reaction in control. More importantly, though, the risk assessment included the methods to contain the reaction in the event of a release through foreseeable causes. They employed a well-written “What-If” type of risk assessment. With the containment in place, the overall risk of the research to the organization was determined to be acceptable and the procedure approved.

Risk acceptance in research, especially cutting-edge research, is necessary in order for scientific discovery. One of our most important jobs as safety professionals is to communicate risk and how that risk is managed to organizational decision-makers.

Want to take your EHS Team to “Best in Class” but don’t quite know where to start? Call Midwest Chemical Safety, LLC, 217-971-6047 or contact me by email at harry@midwestchemsafety.com See the original LinkedIn Post Here.